Textile fabrics (such as cotton, linen, silk, chemical fiber) are soft and elastic. Traditional cutting methods can easily cause material deformation or stretching. When cutting multiple layers of fabric, the bottom layer and the upper layer are easily misaligned, affecting the precision of the finished product. Heat affects the edge carbonization, and chemical fiber fabrics are prone to melt adhesion. Small batch customization costs are high, labor costs are high, nesting utilization is low, and material waste is serious. Using a vibrating knife automatic fabric cutting machine for zero heat cutting protects the fabric fiber structure, does not require secondary edge locking, and has a cutting error of 0.1 ~ 0.2mm, which meets the needs of high-end clothing manufacturing, has no dust pollution, and improves the utilization rate of materials, especially some precious and high-cost textile fabrics. Multiple layers can be cut at one time without the problem of multiple layer misalignment, and will not cause material deformation and stretching.

|

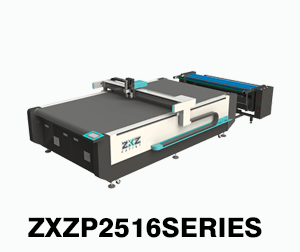

Product Model |

|

|

|

| Cutting Area | 2500mm x 1600mm | ||

| Cutting Speed | 200-2000mm/s (Due to diffderent materials, will effect) | ||

| Cutting Thickness | ≤70mm | ||

| Cutting Tolerance | 0.1-0.2mm | ||

| Material Fixed Way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption | ||

| Countertop Type | Automatic Feeding | ||

| Rated Power | 9KW | 11KW | |

| Driven System | Servo motor / Linear guide rail / Gear rack / Vacuum pump | ||

| Motor | Delta | ||

| Nesting Software | ET Automatic nesting module improves utilization rate by more than 20% compared with manual operation | ||

| Data Format | DLT / PLT / PDF / AI | ||

| Transmisson Interface | Ethernet port | ||

| Voltage | 380V+/-10%; 50HZ | ||

|

|

|

|

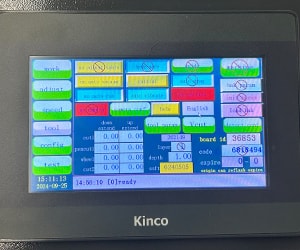

Multifunctional control system Integrates multiple cutting modes with real-time parameter adjustment for higher efficiency. |

Multiple tool holder cutting tools Supports quick tool changes and handles a wide range of flexible materials with precision. |

Aviation aluminum adsorption platform Strong hold, zero shake—keeps materials flat and steady even at top speed. |

|

|

|

|

Large CCD panoramic visual positioning Captures the full layout at once—auto-detects edges and marks for precise positioning. |

Projector Projects cutting paths in real time—makes manual alignment fast and intuitive. |

Square slider guide Delivers smoother motion and enhanced durability for long-term stable operation. |

APPLICATION SAMPLES

In the clothing fabric industry, vibrating knife cutting machines are widely used for precise cutting of various textile materials, composite fabrics and functional fabrics. Especially suitable for mass production and personalized customization, the main materials for cutting:

Vibrating knife cutting technology has been widely used in garment manufacturing, customized clothing, sportswear, functional clothing and protective clothing and other fields, bringing a more efficient and accurate intelligent production model to the clothing industry.

|

|

|

|

|

|