The hardness of different parts of leather materials varies greatly (such as first-layer leather and second-layer leather), and the fiber nature and fiber direction of leather affect the cutting quality. The heat of traditional cutting causes carbonization of the edges, which affects the texture of the leather and produces a strong odor. If manual cutting is used, it is not only inefficient, but also has large precision errors. It also takes a long time and has high labor costs. Traditional cutting methods waste materials seriously, and the nesting utilization rate is ≤70%, making it difficult to accept large orders. If a leather cutting cnc machine is used, it can be configured with CCD, projector, nesting software, etc., and fast and accurate cutting can be achieved, and the error can be controlled within 0.1~0.2mm, and the material utilization rate is increased to 95%. Using optimized software for cutting layout, zero heat is generated during the cutting process, the edges will not be burned, and the cut surface is smooth. Automatic feeding can be configured, and leather punching is supported by switching cutting tools.

|

Product Model |

|

| Working Area | 2500mm x 1600mm |

| Cutting Speed | 800-1200mm/s (Due to different materials,will effect) |

| Cutting Tolerance | +/-0.2mm |

| Cutting Tool | Oscillating knife cutting tool / Driven rotary knife cutting tool / Punching tool / Marking pen |

| Countertop Type | Automatic feeding / Fixed table |

| Material Fixed Way | Alumium bellows type vacuum adsorption platform, partition / follow adsorption |

| Cutting Thickness | ≤70mm |

| Rated Power | 9KW |

| Drive System | Servo motor / Linear guide rail / Gear rack / Vacuum pump |

| Motor | Delta |

| Nesting Software | ET Automatic nesting module improves utilization rate by more than 20% compared with manual operation |

| Data Format | DXF / PLT / PDF / AI |

| Transmission Interface | Ethernet Port |

| Volatage | 380V+/-10%;50HZ |

|

|

|

|

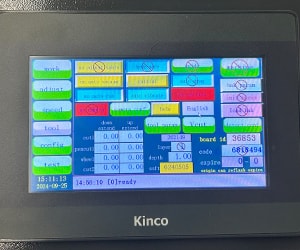

Multifunctional control system Integrates multiple cutting modes with real-time parameter adjustment for higher efficiency. |

Multiple tool holder cutting tools Supports quick tool changes and handles a wide range of flexible materials with precision. |

Aviation aluminum adsorption platform Strong hold, zero shake—keeps materials flat and steady even at top speed. |

|

|

|

|

Large CCD panoramic visual positioning Captures the full layout at once—auto-detects edges and marks for precise positioning. |

Projector Projects cutting paths in real time—makes manual alignment fast and intuitive. |

Square slider guide Delivers smoother motion and enhanced durability for long-term stable operation. |

In the leather industry, leather cutting cnc machine is widely used for high-precision cutting in footwear and bag manufacturing. Main materials for cutting:

In the footwear and bag manufacturing industry, the vibrating knife cutting machine has become an important tool for improving production efficiency, reducing costs, and improving quality, helping brands achieve high-end customization and large-scale production.

|

|

|

|

|

|