Automotive interior materials include genuine leather, artificial leather, fabric, foam, composite materials, etc. The hardness, thickness and cutting characteristics of each material vary greatly. Interior parts usually require high-precision cutting (±0.1mm), which is difficult to meet with traditional cutting methods. The die cutting method is only suitable for large-volume orders, and small-volume orders are difficult to achieve. Secondly, the heat generated can easily damage the edge of the material. For factories that produce small-volume personalized products, the mold opening cost is high, the delivery cycle is long, the customer churn rate is high, and the labor cost is increased. The cnc blade cutting machine is driven by a servo motor, and the cutting error is 0.1mm ~ 0.2mm. The edge of the cut material is smooth and not damaged. Cutting and punching are achieved through cutting tools.

|

Product Model |

|

| Cutting Area | 2500mm x 1600mm |

| Cutting Speed | 1500mm/s |

| Cutting Tolerance | +/-0.2mm (The tolerrance may vary due to different materials) |

| Countertop Type | Automatic feeding / Fixed table |

| Cutting Tool | Oscillating knife cutting tool / Punching tool |

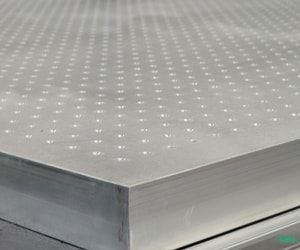

| Material Fixed Way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

| Rated Power | 9KW |

| Cutting Thickness | ≤50mm (Determined according to specific materials) |

| Drive System | Servo motor / Linear guide rail / Rack etc. |

| Motor | Delta (Other brands can be selected upon request) |

| Positioning Accuracy | Servo motor / Linear gu |

| Data Format | DLT / PLT / PDF / AI |

| Transmission Interface | Ethernet port |

| Volatge | 380+/-10%; 50HZ |

|

|

|

|

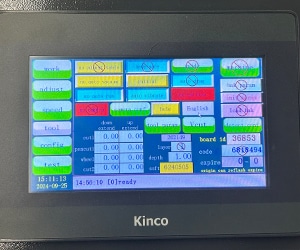

Multifunctional control system Integrates multiple cutting modes with real-time parameter adjustment for higher efficiency. |

Aviation aluminum adsorption platform Strong hold, zero shake—keeps materials flat and steady even at top speed. |

Multiple tool holder cutting tools Supports quick tool changes and handles a wide range of flexible materials with precision. |

|

|

|

|

Square slider guide Delivers smoother motion and enhanced durability for long-term stable operation. |

Servo Motor Stable torque output and quick response—drives every cut with consistent accuracy. |

Gear Rack Provides rigid linear transmission—built for high-speed precision without backlash. |

In the automotive interior industry, cnc blade cutting machine is widely used for precise cutting of various soft materials, composite materials and environmentally friendly materials. They are suitable for small batch customization and complex shape cutting. Applicable materials:

Vibrating knife cutting technology has been widely used in many automotive interior fields such as car seats, door panels, instrument panels, steering wheel covers, roofs, sound insulation and heat insulation systems, providing automakers with efficient and precise intelligent cutting solutions.

|

|

|

|

|

|