The thickness of household carpets varies (5-20mm), and the hardness of different parts varies greatly (such as fluff and backing). The surface texture of the carpet (such as embossing and pattern) is easily damaged during cutting, affecting the appearance of the finished product. Laser cutting causes edge carbonization. Chemical fiber carpets are prone to melting and adhesion, and there is a strong odor when cutting. Manual cutting has low precision and low efficiency. The vibration knife cnc carpet cutting machine has a cutting accuracy of 0.2mm, which meets the needs of high-end household carpet manufacturing, has no heat impact, protects the surface texture and texture of the carpet, and can cut personalized shapes. One device is compatible with all categories of household carpet materials such as wool, chemical fiber, and thick backing.

|

Product Model |

|

| Cutting Area | 2500mm x 1600mm |

| Cutting Speed | 1500mm/s |

| Cutting Tolerance | +/-0.2mm (The tolerrance may vary due to different materials) |

| Countertop Type | Automatic feeding / Fixed table |

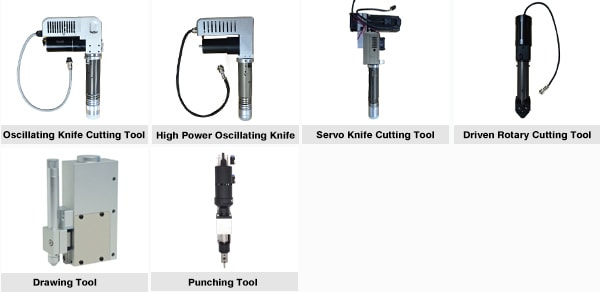

| Cutting Tool | Oscillating knife cutting tool / Punching tool / Driven rotary cutting tool / Marking pen |

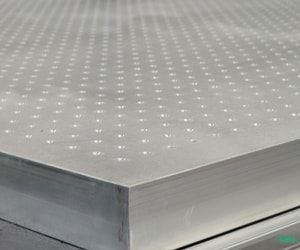

| Material Fixed Way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

| Rated Power | 9KW |

| Cutting Thickness | ≤50mm (Determined according to specific materials) |

| Drive System | Servo motor / Linear guide rail / Rack etc. |

| Motor | Delta (Other brands can be selected upon request) |

| Positioning Accuracy | Servo motor / Linear gu |

| Data Format | DLT / PLT / PDF / AI |

| Transmission Interface | Ethernet port |

| Volatge | 380+/-10%; 50HZ |

|

|

|

|

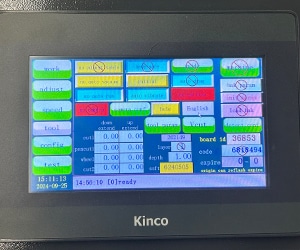

Multifunctional control system Integrates multiple cutting modes with real-time parameter adjustment for higher efficiency. |

Aviation aluminum adsorption platform Strong hold, zero shake—keeps materials flat and steady even at top speed. |

Multiple tool holder cutting tools Supports quick tool changes and handles a wide range of flexible materials with precision. |

|

|

|

|

Square slider guide Delivers smoother motion and enhanced durability for long-term stable operation. |

Intelligent nesting software Reducing the waste of scraps and increasing the material utilization rate by 10%-30%. |

CCD panoramic vision positioning Captures high-resolution images, scans the material surface in real time, identifies defects, marks points, and automatically adjusts the cutting path |

In the carpet industry, cnc carpet cutting machinewidely us is used to accurately cut various carpet materials, whether commercial, household, automotive interior, or engineering carpets, providing efficient, dust-free, no-scorching, no-burr cutting effects, suitable for large-format, special-shaped cutting, customized processing and other needs, applicable materials:

Vibrating knife cutting machines have been widely used in home carpets, commercial carpets, exhibition carpets, automotive carpets, engineering carpets and other fields, providing carpet manufacturers with intelligent, efficient and precise cutting solutions.

|

|

|

|

|

|