Traditional packagng cutting machines require manual feeding, long mold change time, large cutting errors, difficult cutting of complex graphics, and easy waste of materials. Small batch orders are prone to losing customers, and are also prone to losing some personalized, high value-added product orders. The vibration knife increases the rotation speed, adds nesting software, and can also add an automatic feeding platform. The servo motor increases the cutting accuracy by +/-0.2mm. Using various cutting tools, it can complete multiple tasks such as cutting, creasing, punching, etc. The qualified rate of finished products is increased to 95%, reducing labor costs.

|

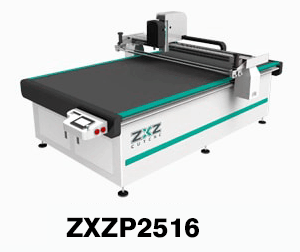

Products Model

|

|

|

|

| Cutting Area | 2500mm x 1600mm | 400mm x 600mm | 600mm x 800mm |

| Cutting Speed | 1500mm/s | ||

| Cutting Tolerance | +/-0.2mm (The tolerrance may vary due to different materials) | ||

| Cutting Tool | Oscillating knife cutting tool / Creasing cutting tool / Kiss-Cut cutting tool / Dotted Line Tool / V-cutting Tool | ||

| Countertop Type | Automatic feeding / Fixed table | Automatic feeding | |

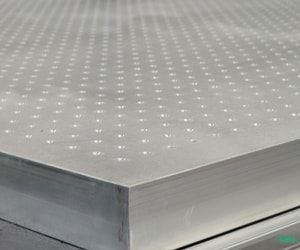

| Material Fixed Way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption | ||

| Cutting Thickness | ≤50mm | 2mm - 5mm | |

| Rated Power | 9KW | 2.5KW / 3.2KW | |

| Drive System | Servo motor / Linear guide rail / Rack etc. | ||

| Positioning Accuracy | 0.05mm | ||

| Motor | Delta / DORNA (Other brands can be selected upon request) | ||

| Data Format | DLT / OLT / CF2 / XML | ||

| Transmission Interface | Ethernet port | ||

| Volatge | 380+/-10%; 50HZ | 220V / 380V +/-10%; 50HZ | |

|

|

|

|

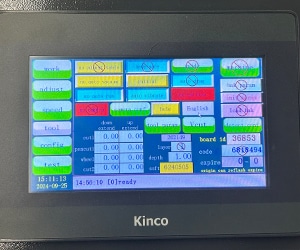

Multifunctional control system Integrates multiple cutting modes with real-time parameter adjustment for higher efficiency. |

Aviation aluminum adsorption platform Strong hold, zero shake—keeps materials flat and steady even at top speed. |

Multiple tool holder cutting tools Supports quick tool changes and handles a wide range of flexible materials with precision. |

|

|

|

|

Square slider guide Delivers smoother motion and enhanced durability for long-term stable operation. |

Servo Motor Stable torque output and quick response—drives every cut with consistent accuracy. |

Gear Rack Provides rigid linear transmission—built for high-speed precision without backlash. |

In the packaging industry, vibrating knife cardboard cutting machine is widely used in the processing of cartons, foam, honeycomb panels, plastic panels, corrugated paper, leather packaging and other materials. Suitable for production needs such as customized packaging, cushioning lining, display packaging, etc. Applicable materials

The cardboard cutting machine provides the packaging industry with efficient, intelligent and refined processing solutions, especially suitable for the production and manufacturing of high-end packaging, customized packaging and industrial protective packaging.