Home materials include curtains, pillowcases, cushions, tablecloths, coasters, DIY decals, blankets, etc., leather, fabric, foam, composite materials, etc. The hardness, thickness and cutting characteristics of each material vary greatly. The cnc textile cutting machine is specialized in cutting flexible materials. By switching tools, it can adapt to a variety of materials, and the cutting error is +/-0.2mm, which can meet the needs of most high-end products. The cnc textile cutting machine cuts the shape by the blade frequency vibration. There is no laser, so there will be no problem of edges being burned and bonded together. It can cut multiple layers at the same time, and by adding beams and tool module groups, the cutting speed can be greatly improved. Some small batch personalized factories can use this machine to save labor, save costs, have a short learning cycle, and get started quickly.

|

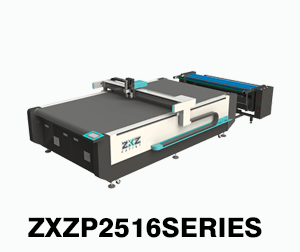

uct Model |

|

|

|

| Cutting Area | 2500mm x 1600mm | ||

| Cutting Speed | 200-2000mm/s (Due to diffderent materials, will effect) | ||

| Cutting Thickness | ≤70mm | ||

| Cutting Tolerance | 0.1-0.2mm | ||

| Material Fixed Way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption | ||

| Countertop Type | Automatic Feeding | ||

| Rated Power | 9KW | 11KW | |

| Driven System | Servo motor / Linear guide rail / Gear rack / Vacuum pump | ||

| Motor | Delta | ||

| Nesting Software | ET Automatic nesting module improves utilization rate by more than 20% compared with manual operation | ||

| Data Format | DLT / PLT / PDF / AI | ||

| Transmisson Interface | Ethernet port | ||

| Voltage | 380V+/-10%; 50HZ | ||

|

|

|

|

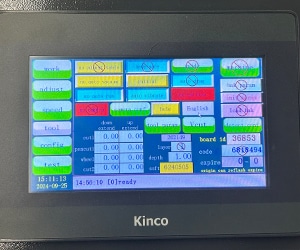

Multifunctional control system Integrates multiple cutting modes with real-time parameter adjustment for higher efficiency. |

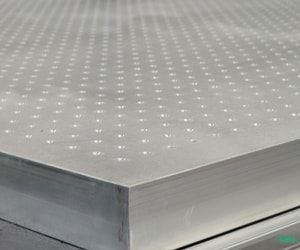

Aviation aluminum adsorption platform Strong hold, zero shake—keeps materials flat and steady even at top speed. |

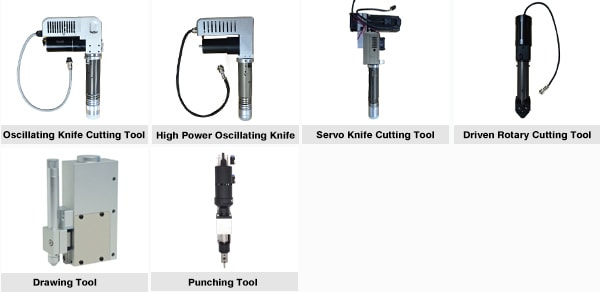

Multiple tool holder cutting tools Supports quick tool changes and handles a wide range of flexible materials with precision. |

|

|

|

|

Square slider guide Delivers smoother motion and enhanced durability for long-term stable operation. |

Intelligent nesting software Reducing the waste of scraps and increasing the material utilization rate by 10%-30%. |

CCD panoramic vision positioning Captures high-resolution images, scans the material surface in real time, identifies defects, marks points, and automatically adjusts the cutting path |

In the home furnishing industry, cnc textile cutting machine is widely used for precise cutting of soft furnishings, furniture manufacturing, and home decoration materials. They are suitable for customization, special-shaped, mass production and other needs. Applicable materials:

|

|

|

|

|

|