Small batches of complex gaskets require smaller errors, and the cutting accuracy must reach ±0.2mm. Traditional cutting methods are difficult to meet. Thermal effects can cause carbonization of rubber and silicone edges, affecting sealing performance. Water cutting consumes a lot of water resources, and requires drying after wet cutting, resulting in serious material waste. Small batch orders are difficult to undertake and are highly dependent on labor. The benefits of the cnc gasket cutting machine are that the error is within 0.2mm, the cut surface is smooth, there is no thermal effect, it will not cause the edge to burn, the cutting speed is fast, it supports continuous operation, can cut a variety of complex graphics, reduce dust, especially asbestos-free/asbestos boards, requires less labor, and is easy to use.

|

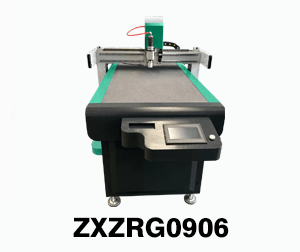

Product Model |

|

|

| Cutting Area | 2500mm x 1600mm | 900mm x 600mm |

| Cutting Speed | 1500mm/s (Due to different materials,will effect) | |

| Cutting Tolerance | +/-0.2mm - 0.3mm (The tolerrance may vary due to different materials) | |

| Cutting Tool | 100W/350W Oscillating knife cutting tool / Servo knife cutting tool / Pneumatic knife cutting tool | |

| Countertop Type | Automatic feeding / Fixed table | |

| Material Fixed Way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption | |

| Cutting Thickness | 1mm - 15mm (Determined according to specific materials) | |

| Rated Power | 9KW | 2.2KW |

| Drive System | Servo motor / Linear guide rail / Rack etc. | |

| Positioning Accuracy | 0.05mm | |

| Motor | Delta / DORNA (Other brands can be selected upon request) | |

| Data Format | DLT / PLT / PDF / AI | |

| Transmission Interface | Ethernet port | |

| Volatge | 380V+/-10%; 50HZ | 220V+/-10%; 50HZ |

|

|

|

|

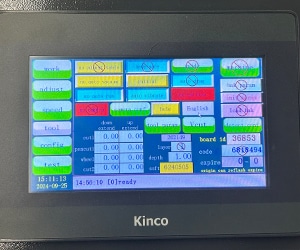

Multifunctional control system Integrates multiple cutting modes with real-time parameter adjustment for higher efficiency. |

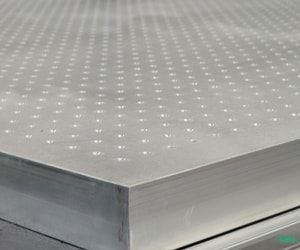

Aviation aluminum adsorption platform Strong hold, zero shake—keeps materials flat and steady even at top speed. |

Multiple tool holder cutting tools Supports quick tool changes and handles a wide range of flexible materials with precision. |

|

|

|

|

Square slider guide Delivers smoother motion and enhanced durability for long-term stable operation. |

Servo Motor Stable torque output and quick response—drives every cut with consistent accuracy. |

Gear Rack Provides rigid linear transmission—built for high-speed precision without backlash. |

In the gasket industry, cnc gasket cutting machine is widely used for precise cutting of various sealing materials, insulating materials and high-performance composite materials. Especially suitable for small batch customization and high-precision seal production, applicable materials:

Vibration knife cutting technology has been widely used in many industries such as automotive industry, pipeline sealing, electrical equipment, machinery manufacturing, aerospace, medical equipment**, etc., providing more efficient and accurate intelligent cutting solutions for seal production.

|

|

|

|

|

|