Aramid fiber has high toughness, and is prone to fluffing and loosening when cutting, and has a high risk of delamination (weak bonding between matrix resin and fiber). Traditional laser cutting will cause edge carbonization, mechanical blades will wear quickly, and the burrs may need to be polished again; the dust generated when cutting glass fiber cloth is very harmful and may cause respiratory diseases. Traditional water jet cutting is inefficient, and dry cutting will generate a large amount of glass fiber dust, which requires additional dust removal equipment and increases costs; carbon fiber cloth has high hardness, and the fiber direction of carbon fiber cloth affects the cutting quality. Traditional cutting methods are difficult to take into account the fiber characteristics in different directions.

The carbon fiber cutting machine use oscillating knife cutting tool controls the cutting error at about 0.2mm through high-frequency micro-vibration. Most products do not generate heat and will not damage the material itself. The vacuum adsorption system can firmly adsorb the material on the cutting platform, and this kind of cutting greatly reduces dust pollution and reduces the harm to workers. Through real-time detection and adjustment, the qualified rate can be greatly improved, and the vibration large cutting machine has multi-material adaptability and supports the processing of complex patterns, which increases added value and improves production efficiency.

|

Products Model |

|

| Cutting Area | 2500mm x 1600mm |

| Cutting Speed | 1500mm/s |

| Cutting Tolerance | +/-0.2mm (The tolerrance may vary due to different materials) |

| Cutting Tool | Oscillating knife cutting tool / Driven rotary cutting tool / Punching tool / Drawing tool |

| Countertop Type | Automatic feeding / Fixed table |

| Material Fixed Way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

| Cutting Thickness | ≤80mm (Determined according to specific materials) |

| Rated Power | 9KW |

| Drive System | Servo motor / Linear guide rail / Rack etc. |

| Positioning Accuracy | 0.05mm |

| Motor | Delta (Other brands can be selected upon request) |

| Data Format | DLT / PLT / PDF / AI |

| Transmission Interface | Ethernet port |

| Volatge | 380+/-10%; 50HZ |

|

|

|

|

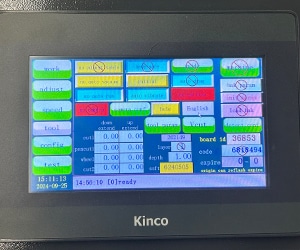

Multifunctional control system Integrates multiple cutting modes with real-time parameter adjustment for higher efficiency. |

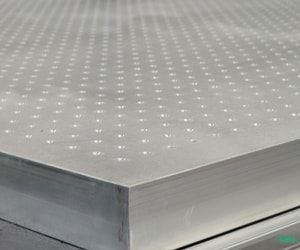

Aviation aluminum adsorption platform Strong hold, zero shake—keeps materials flat and steady even at top speed. |

Multiple tool holder cutting tools Supports quick tool changes and handles a wide range of flexible materials with precision. |

|

|

|

|

Square slider guide Delivers smoother motion and enhanced durability for long-term stable operation. |

Servo Motor Stable torque output and quick response—drives every cut with consistent accuracy. |

Gear Rack Provides rigid linear transmission—built for high-speed precision without backlash. |

APPLICATION SAMPLES

In the composite materials industry, carbon fiber cutting machine is widely used for high-precision cutting of a variety of composite materials. These materials usually have the characteristics of lightweight, high strength, wear resistance, high temperature resistance, and impact resistance. They are used in aerospace, automobile manufacturing, architectural decoration, electronics industry and other fields. The following are the common classifications of composite materials that can be cut by vibration knives:

|

|

|

|

|

|