|

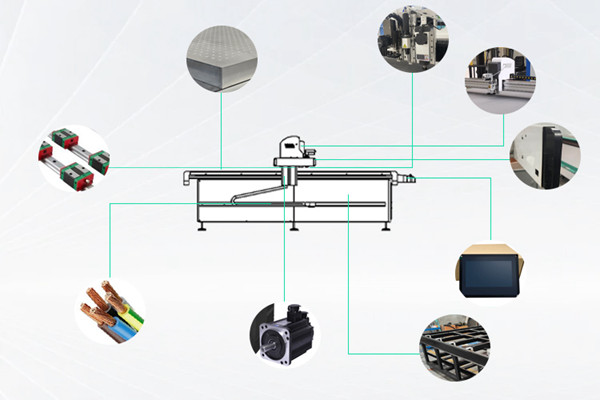

CNC Knife Cutting Machine |

|

|

|

|

|

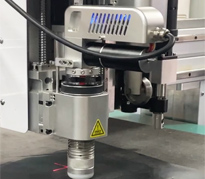

Knife Cutting Tool |

|

|

|

|

|

Smart Control System |

CNC knife cutting machine will configure suitable knives according to cutting requirements and cutting materials, including the hardness and thickness of the material, so as to ensure efficiency and accuracy.

The cnc knife cutting machine mainly uses a high-frequency vibration device to drive the knife for cutting operations. If cutting gaskets, the oscillating cutting machine is mainly used here, because by cutting three different tool heads, it can cut 1mm - 15mm (depending on the material) gaskets, covering many industries. This oscillating cutting machine can not only cut rubber gasket, but also involves many other materials, such as silicone board, foam board, pearl cotton board, PTFE board, asbestos board, asbestos-free fiberboard, etc., it can also be called "gasket cutting machine cnc".

When cutting flexible materials, laser cutting machine can be used, but CNC knife cutting machine has better cutting effect. For example, when cutting rubber, laser machine may burn the edge of rubber, produce smoke, or the edge cutting is not clean, but rubber gasket cutting machine CNC knife will not have the above phenomenon, because rubber gasket cutting machine CNC uses blade cutting.

|

|

|

Vibrating Knife |

|

| The vibrating knife is suitable for cutting medium density materials. Different cutting angles of blades can be installed according to the material. | |

Processable materials: |

advertising KT board, foam board, ABS plastic, corrugated plastic board, corrugated paper, cardboard, gray board, wire ring mat, carpet, rubber gaskets and sealing, carbon fiber prepreg, etc.: |

Pneumatic Knife |

|

| Compressed air driven, cutting hard and dense materials | |

Processable materials: |

Asbestos sheet, non-asbestos sheet, graphite, PTFE, rubber sheet, silicone sheet, graphite composite sheet, etc. |

V-Cutting Knife |

|

| Perform "V" groove processing without penetrating the product itself, and obtain different cutting effects by changing the blade inclination | |

Processable materials: |

Soft glass, PVC, honeycomb board, KT board, vertical corrugated paper, grey cardboard and other materials. |

Half cutting knife |

|

| The tool cuts through the top of the material without damaging the bottom | |

Processable materials: |

Self-adhesive stickers, car stickers, reflective stickers, magnetic stickers, PP paper, PP adhesive, rubber cloth, imitation cloth, cardboard, soft glass and other materials. |

There are more CNC cutting machine knife, please contact us for more information.

In cutting rubber products, oscillating cutting machine can meet most of the gasket needs

CNC knife cutting machine, can easily produce complex geometries and detailed designs that would be difficult or impossible with traditional cutting methods.Once a design is programmed into the CNC machine, it can produce identical parts repeatedly without variations, ensuring consistent quality.