Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: zxzcnc@chn-rubber.com

WhatsApp: 008618222051167

Cutting durable, often thick or coated outdoor materials like waterproof fabrics, tarpaulins, and tent materials,achieving consistent precision on these robust textiles is crucial for product performance and longevity. A digital fabric cutter provides a specialized automated solution engineered to meet these demanding requirements. This equipment revolutionizes the cutting process, ensuring reliable accuracy and efficiency specifically for the outdoor and technical textile sectors, enabling the creation of high-quality products. Exceptional cutting precision ensures clean edges and accurate dimensions, critical for reliable seam sealing and product assembly in items exposed to the elements. The ability to maintain high operational speed is essential for the volume production of standard covers or complex tent structures. Sophisticated software includes advanced nesting algorithms optimized for reducing waste on expensive outdoor fabrics. Furthermore, the system's robustness allows it to process a wide range of thicknesses and layered materials common in tarpaulins and multi-wall tent fabrics.

| Parameter | ZXZ2516OT |

| Working area | 2500mm x 1600mm |

| Cutting speed | 1200mm/s(Due to different materials,will affect) |

| Cutting tolerance | +/-0.1mm (The tolerance may vary due to different materials) |

| Cutting tool | Oscillating cutting tool / Driven rotary cutting tool / punching tool (V-shape or circle shape) / drawing tool / CCD camera |

| Countertop type | Automatic feeding / Fixed working table |

| Material fixed way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

| Cutting thickness | ≤70mm (Depending on the material, the thickness that can be cut will vary) |

| Rated Power | 9KW |

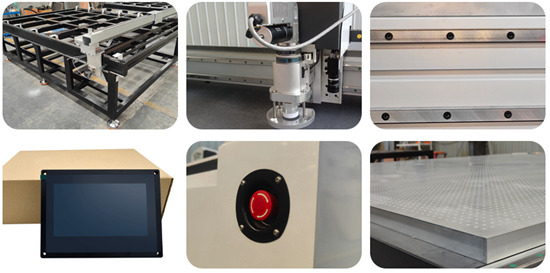

| Drive system | Servo motor, Linear guide rail, Rack |

| Motor | Delta |

| Nesting software | ET automatic nesting module improves utilization rate by more than 20% compared with manual operation |

| Data Format | DXF,PLT,PDF,AI |

| Transmission interface | Ethernet port |

| Fault detection | Automatically detect electrical faults when powered on and push codes to the system |

| Red preview function | Preview the cutting sample before processing to see if it is in the material to prevent misoperation |

| Projection function | Can install projector |

| Frame structure | Carbon dioxide protected welding bed, secondary vibration aging treatment |

| Voltage | AC 110V/220V/380V±10%, 50HZ/60HZ |

Digital fabric cutter employs cutting tools specifically chosen for their capability to handle the resilience and density of outdoor materials, such as powerful oscillating knives, drag knife. A high-performance vacuum system is integrated to firmly hold down the often-slippery or heavy materials, preventing movement and ensuring the accuracy of intricate cuts required for components like tent panels or tarp sections.

Digital fabric cutter is specifically engineered to handle a broad spectrum of outdoor and technical textiles. This includes, but is not limited to, waterproof coated fabrics, heavy-duty tarpaulin materials, diverse types of tent fabrics (including Ripstop and coated nylons/polyesters), canvas, sailcloth, materials used for inflatable structures, outdoor furniture upholstery, and technical textiles for covers and protective gear. Its capabilities support the production of tents, tarps, boat covers, outdoor furniture covers, sails, marquees, industrial curtains, and vehicle protective coverings.