Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Today, as industrial manufacturing moves towards flexibility and digitalization, the vibration knife cutting system of Tianjin ZXZ CNC cutting company takes high-frequency micro-amplitude technology as the core, breaking through the accuracy and efficiency bottleneck of traditional cutting. Through modular cutter head design and intelligent dynamic path algorithm, we provide different cutting solutions for different industries, achieving ±0.2mm stable cutting accuracy on materials with different characteristics. The intelligent typesetting system saves about 10%-20% of materials compared with manual typesetting, without pollution or damage to materials.

|

|

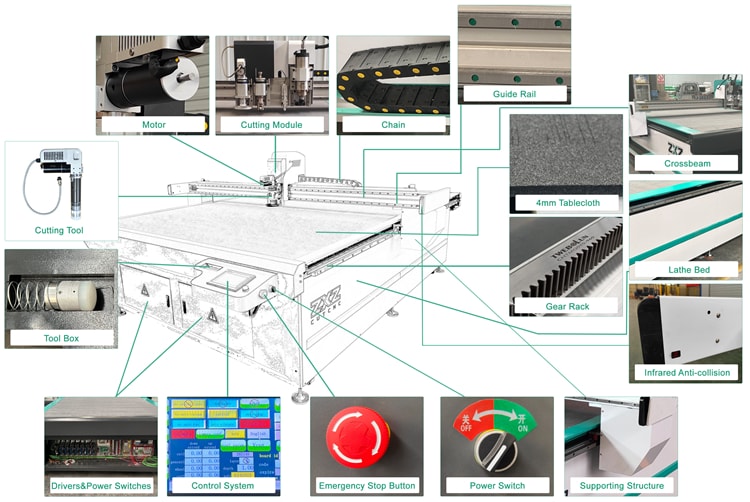

The basic configuration of the machine does not require customers to assemble some parts by themselves, and the machine is equipped with an emergency stop button and infrared sensor. Compared with laser cutting machines and punching machines, CNC knife cutting machines are simpler and more automated. The machine has a strong adsorption capacity and can handle a variety of flexible materials. The cutting area can be customized according to the material being cut, and an automatic feeding platform can be added. This type of machine is relatively low in cost and is more suitable for cutting complex and fine patterns. | |

|

|

||

|

|

The machine includes a range of adaptable cutting tools for a variety of materials and tasks. Operators can switch between various cutting tools and configure settings based on material requirements. Frequent users can save preferred settings for each tool type, streamlining future setups and reducing prep time. | |

|

|

||

|

|

The software supports a variety of design file formats, such as DXF, AI, PDF and SVG, to ensure seamless integration with industry-standard CAD and graphic design software, and allows operators to view machine status and progress in real time; it also comes with 7 smart tools: mechanical motion control system, visual recognition system, CCD recognition system, projection positioning system, leather recognition and positioning system, gasket smart nesting software, fabric smart nesting software; the system language supports other languages in addition to English. The intuitive and clear interface allows operators to easily navigate settings, load designs and start tasks without extensive training. |

| Machine Working: The machine apodts smart control system, mainly uses a high-frequency vibration device to drive the knife for cutting operations. and cut efficiency across various materials, such as rubber, fabric, and foam. This oscillation helps reduce friction and wear on softer or sensitive materials, enabling consistent and precise cuts. |

| Adsorption Materials: In order to fix the material during the cutting process, the machine uses an aviation aluminum honeycomb vacuum adsorption platform, which firmly fixes the material in place through a vacuum pump. This setting prevents the material from sliding during the cutting process, thus achieving highly fine and uniform cutting. |

| Cutting Ability: CNC knife cutting machines can handle materials up to 1mm~100mm thick, offering clean edges without fraying or deformation. This capability is valuable in industries requiring intricate shapes and contours, like packaging ,automotive and clothing, where different material types and densities must be cut with minimal waste. |

| Material Integrity: CNC oscillating knife cutting machine maintain material integrity by avoiding heat. Unlike laser cutters, which can burn or warp heat-sensitive materials, CNC knife cutters employ a sharp blade that oscillates or vibrates to make clean, controlled cuts. This approach is particularly suited for materials like foam, rubber, textiles, and certain plastics, where preserving the material's original texture and edge quality is crucial. |

| Flexible Design with Minimal Setup: Unlike punching machines, which require physical dies for each pattern, CNC oscillating knife cutting machine allow immediate design changes through computer uploads. With no need for costly dies or tool changes, they’re ideal for rapid prototyping and small to medium production runs. This flexibility minimizes setup costs and enables quick turnaround, making CNC knife cutting machines exceptionally cost-effective for custom and intricate projects. |

| Intricate Cutting Precision: CNC oscillating knife cutting machine excel at handling complex shapes and detailed designs, thanks to their controlled blade movements. While punching machines rely on impact and may struggle with fine details, CNC knife cutters achieve clean edges without distortion or stress on the material. This precision is invaluable for applications in packaging, automotive interiors, and signage, where high-quality, detailed cuts are essential. |

By prioritizing versatility, material-friendly cutting, and low setup requirements, CNC oscillating knife cutting machine provide a powerful alternative to laser and punching machines, particularly for industries requiring flexibility and high precision. This approach not only saves costs but also ensures high-quality results across a range of applications.

CONTACT US:

WhatsApp: 008615222735180

Email: cutcnc@chn-rubber.com