Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

Engineered for the demanding requirements of advanced materials processing, our state-of-the-art prepreg cutting machine offers a generous 2500mm x 1600mm work area, ideal for handling large or nested composite plies efficiently. Optionally equipped with an automatic roll feeding system, it seamlessly integrates continuous material unwinding for enhanced productivity with rolled prepregs. As a versatile composite material cutting machine, it provides the essential precision and flexibility needed for industries like aerospace, automotive, and wind energy. This dedicated prepreg cutter utilizes advanced motion control and can be configured with specialized tooling – including a high-frequency oscillating knife for intricate shapes, a driven rotary tool for fast, clean cuts on specific materials, and punching tools for precise registration marks or perforations. It ensures the utmost accuracy and clean edges vital for maintaining material integrity during the layup process, delivering reliable and repeatable results for critical component manufacturing.

| Parameter | ZXZ-P2516 |

| Working area | L 2500mm x W 1600mm |

| Cutting speed | 1200mm/s (Due to different materials,will affect) |

| Cutting toloerance | +/-0.1mm (The tolerance due to different materials) |

| Cutting tool | 100W/350W/400W Oscillating knife / Driven rotary cutting tool / Punching tool |

| Countertop type | Automatic feeding |

| Material fixed way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

| Cutting thickness | ≤50mm (Due to different materials,will affect) |

| Feeding thickness | 120mm |

| Drive system | Servo motor / Linear guide rail / Rack |

| Motor | Delta Brand |

| Nesting software | ET automatic nesting module improves utilization rate by more than 20% compared with manual operation |

| Data format | DXF / PLT / PDF / AI |

| Transmission interface | Ethernet |

| Fault detection | Automatically detect electrical faults when powered on and push codes to the system |

| Red preview function | Preview the cutting sample before processing to see if it is in the material to prevent missoperation |

| Software | CUT / LaserCAD / ET Super nesting / JDsoft |

| Frame structure | Carbon dixide protected welding bed, secondary vibration aging treatment |

| Package | Wooden case |

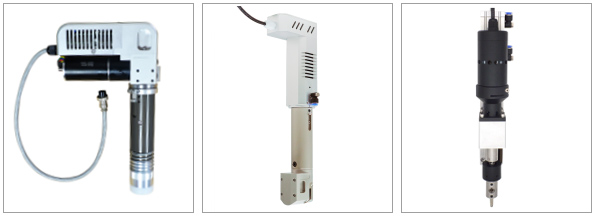

Versatile Tooling Configuration: Supports multiple tool heads, configurable with:

Oscillating Knife: For precise cutting of complex contours, sharp corners, and various prepreg types.

Driven Rotary Knife: Offers high-speed cutting, particularly effective for straight lines and certain fabric-based or dry fiber materials.

Punching Tool: Enables accurate creation of holes.