Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

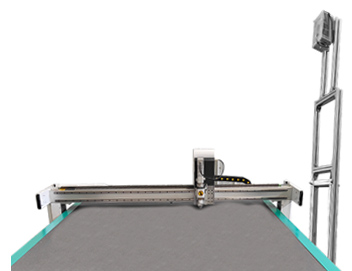

Addressing the stringent demands for efficiency and precision in modern textile production, the automatic textile cutting machine emerges as an essential solution. This system is specifically engineered for high-speed, high-quality fabric processing, revolutionizing traditional cutting methodologies through automation. Its core benefit lies in significantly accelerating the production pace while simultaneously guaranteeing accuracy for every cut, establishing a robust foundation for subsequent manufacturing steps. Implementing this technology enables businesses to effectively manage large-volume production challenges and uphold market competitiveness.

The automated textile cutting system leverages advanced digital control for intelligent operation. Upon importing design patterns, the equipment autonomously plans the optimal cutting path, precisely directing the cutting tool to execute tasks. Integrated automatic feeding and material collection mechanisms ensure continuous production line operation. Sophisticated software works in tandem to maximize fabric layout utilization, minimizing material waste at the source. This level of automation substantially decreases reliance on operator skill, enhancing overall production stability and consistency.

|

|

|

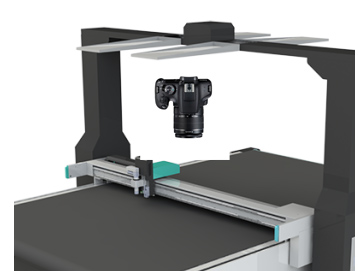

| Large-format material delivery platform | Large CCD panoramic camera positioning | Projector |

|

|

|

| Dual beams | Dual cutting tools shifting | Intelligent material calculation/layout software |

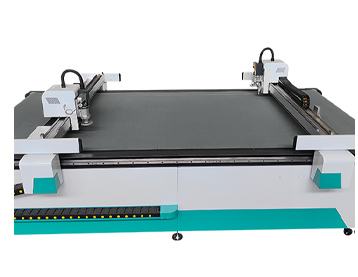

| Model | ZXZL2516 |

| Cutting material |

wool and silk, synthetic fibers like nylon, polyester, and polypropylene, soft PVC and blends of various materials.

|

| Cutting tool | Oscillating Knife 、Round punching 、 Circular knife、Marking pen |

| Cutting thickness | ≤20cm |

| Cutting countertop | 4mm felt |

| Saftey device | Infrared sensors |

| Motor | Delta |

| Guide rail | TW Brand Linear guide |

| Vacuum pump power | 9KW |

| Voltage | 220V / 380V+/-10% |

| Repeated accuracy | ≤0.1mm |

| Translational velocity | 800-1200mm/s |

| Felt | Imported brand |

| Machine weight | 1200KG |

| Warranty | 1 year |

|

Nesting software

|

ET automatic nesting module improves utilization rate by more than 20% compared with manual operation

|

|

Data Format

|

DXF,PLT,PDF,AI

|

|

Transmission interface

|

Ethernet port

|

|

Projection function

|

Can install projector

|

The automatic textile cutting machine demonstrates broad material compatibility. It effectively handles natural fibers such as cotton, linen, silk, and wool, as well as synthetic fibers like polyester and nylon, including blends. Its robust cutting power makes it applicable across various sectors, including apparel manufacturing, home textiles (e.g., upholstery, curtains), industrial textiles (e.g., tents, filtration media), and automotive interiors. The equipment's versatility caters to the diverse requirements of clients in numerous industries.