Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: zxzcnc@chn-rubber.com

WhatsApp: 008618222051167

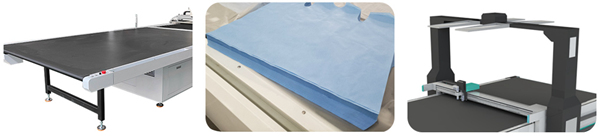

This sophisticated CNC textile cutter operates under Computer Numerical Control (CNC), enabling the precise translation of digital pattern data directly into cutting actions on the textile. The system employs a range of specialized cutting heads, which might include oscillating blades, rotary cutters, drag knive , selected based on the specific fabric type and required cut quality. A robust material handling setup, typically featuring automated feeding mechanisms, tension control, and a powerful vacuum hold-down system, ensures the fabric remains flat and stable throughout the cutting cycle. This guarantees that intricate shapes and precise lines are accurately reproduced from the digital design.

Primary capability is its outstanding cutting fidelity, consistently producing clean edges and accurate dimensions essential for high-quality finished goods. Its rapid operational speed dramatically increases production capacity and reduces lead times. Integrated software includes intelligent nesting algorithms that efficiently arrange pattern pieces on the material, maximizing yield and significantly reducing fabric waste. The modular tool carriage supports quick exchanges between different cutting tools, allowing adaptation to a wide variety of textile types and thicknesses without extensive retooling. Automated material feeding and handling contribute to a continuous, smooth production flow.

| Model | ZXZATF2516 | ZXZATF1630 | ZXZATF1830 |

| Cutting Area | 2500mm x 1600mm | 1600mm x 3000mm | 1800mm x 3000mm |

| Cutting Speed | 2000mm/s | ||

| Cutting tolerance | +/-0.1mm | ||

| Cutting Tool | Osillating Knife / Driven Rotary / Puching Tool / Drawing Tool | ||

| Countertop Type | Automated Feeding | ||

| Material Fixed Way | Alumium bellows type vacuum adsorption platform, parttion / follow adsorption | ||

| Cutting Thickness | ≤ 50mm | ||

| Rated Power | 9KW / 11KW | ||

| Drive System | Servo motor / Linear guide rail / Rack | ||

| Motor | Delta | ||

| Nesting Software | ET automatic nesting module | ||

| Data Format | DXF,PLT,PDF,AI | ||

| Transimission Interface | Ethernet port | ||

| Voltage | AC 240V /380V+/-10%, 50HZ OR 60HZ | ||

Extended working area processing: CNC textile cutter system accommodates extended material formats, capable of handling extra-wide or exceptionally long rolls and sheets. This is particularly advantageous for large-scale projects like banners, wide upholstery, or complex layouts requiring full-width fabric sections, expanding production possibilities.

Efficient Multi-Layer Cutting: Designed for multi-layer fabric cutting, the machine can process stacked plies of certain textiles simultaneously with precision. This capability dramatically increases throughput for high-volume production of identical or similar components, offering significant time and labor savings compared to single-ply cutting.

Panoramic Vision System: An integrated panoramic vision system provides comprehensive camera coverage of the entire cutting area. This technology is crucial for precisely aligning cuts with repeating patterns on printed fabrics (pattern matching), accurately recognizing registration marks, or optimizing the placement of cuts around flaws or specific areas on the material surface.

This CNC textile cutter technology demonstrates remarkable versatility across a broad spectrum of textile materials. It effectively processes natural fibers such as cotton, linen, silk, and wool; synthetic fabrics including polyester, nylon, elastane, and blends; various non-woven fabrics; high-performance technical textiles; and composite reinforcement preforms. Its adaptability makes it an invaluable asset in numerous industries. Applicable sectors include apparel manufacturing (clothing, fashion accessories), home furnishings (upholstery, drapery, bedding), automotive interiors, aerospace components, industrial textiles (filtration, protective wear), outdoor gear, and marine applications.