Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

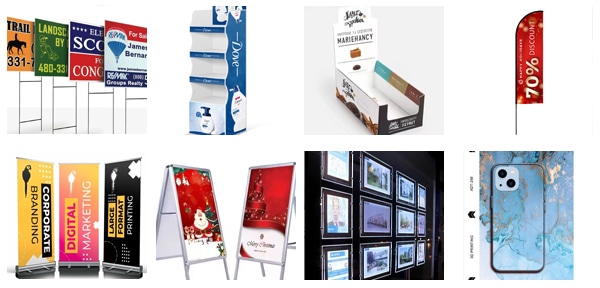

The advertising cutting machine—also known as the flatbed digital cutting machine and CNC digital cutting machine—is a single, integrated solution engineered for precision cutting across various materials. Designed to handle tasks such as producing signage, decals, and packaging, it utilizes advanced CNC technology combined with a flatbed platform to ensure clean, accurate cuts while accommodating different material sizes and thicknesses. This versatile machine is tailored for the demands of advertising and custom fabrication, providing consistent performance and high-quality output.

| Parameter | #2516 Machine |

| Working area | L 2500mm x W 1600mm |

| Cutting speed | 1200mm/s (Due to different materials,will affect) |

| Cutting toloerance | +/-0.01mm (The tolerance due to different materials) |

| Cutting tool | 100W Oscillating knife / Creasing tool / Half-cut / CCD / Round knife |

| Countertop type | Automatic feeding |

| Material fixed way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

| Cutting thickness | ≤50mm (Due to different materials,will affect) |

| Feeding thickness | 120mm |

| Drive system | Servo motor / Linear guide rail / Rack |

| Motor | Delta |

| Nesting software | ET automatic nesting module improves utilization rate by more than 20% compared with manual operation |

| Data format | DXF / PLT / PDF / AI |

| Transmission interface | Ethernet |

| Fault detection | Automatically detect electrical faults when powered on and push codes to the system |

| Red preview function | Preview the cutting sample before processing to see if it is in the material to prevent missoperation |

| Software | CUT / LaserCAD / ET Super nesting / JDsoft |

| Frame structure | Carbon dixide protected welding bed, secondary vibration aging treatment |

| Package | Wooden case |

ZXZ CNC digital cutting features a high-precision digital system that executes full-size, kiss, milling, punching, inkjet, and drawing marking functions. It supports a wide range of tool heads—including oscillating, pneumatic, high-power vibrating, circular, V-shaped, drag, creasing, dotted, punching, —and offers diverse visual positioning options via CCD, panoramic, or projection methods.

Its blade-based cutting method produces clean, straight edges free of burrs, discoloration, or other imperfections, operating up to five times faster than laser cutters and adjustable to suit various material thicknesses.

Key components include a high-precision servo motor (with Delta) . The machine’s frame is constructed from thick-walled seamless steel, precisely machined to ensure durability and accuracy. Additionally, a magnesium-aluminum alloy vacuum table—enhanced through advanced surface treatments—ensures uniform suction, while an integrated aluminum vacuum pump with a built-in silencer reduces noise by 35%. Safety measures, such as infrared sensors, collision detection, and an emergency stop, further enhance reliable operation.