Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

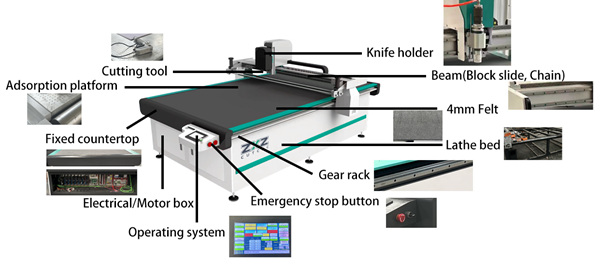

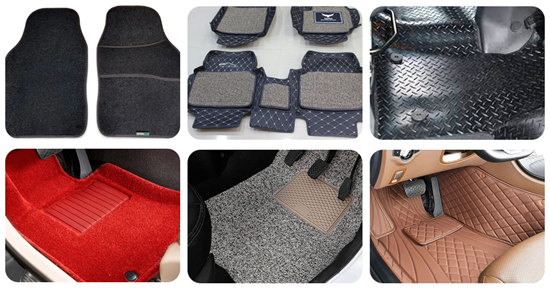

Manufacturing high-quality, perfectly fitted car mats for diverse vehicle models requires specialized equipment capable of handling varied materials and complex geometries. Car mat cutting machine offers an automated, precision-engineered solution designed specifically for the automotive industry. This system transforms the traditional cutting process, ensuring accuracy and consistency for every mat produced. Its primary function is to empower manufacturers to efficiently process automotive-grade materials into vehicle-specific floor mats, enhancing both production speed and product quality. CNC car mat cutting machine operations rely on advanced Computer Numerical Control (CNC) technology to accurately apply digital design data, typically from a designed CAD file, directly to the mat material. Specialized cutting tools such as rugged oscillating knives, drag knives are used, which can be selected based on the type of automotive material (e.g. rubber carpet, tufted, EVA, TPE). These tools are carefully designed to provide clean, accurate cuts on dense, multi-layered automotive fabrics and composites. A powerful vacuum hold-down system securely holds the material during the cutting process, preventing any movement that could affect the accuracy of complex, specific shapes and contours.

| Parameter | ZXZ2516 |

| Working area | 2500mm x 1600mm |

| Cutting speed | 2000mm/s(Due to different materials,will affect) |

| Cutting tolerance | +/-0.2mm (The tolerance may vary due to different materials) |

| Cutting tool | Oscillating cutting tool / Round knife tool / punching tool (V-shape or circle shape) / drawing tool / CCD camera |

| Countertop type | Fixed working table OR Automatic feeding table |

| Material fixed way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

| Cutting thickness | ≤35mm (Depending on the material, the thickness that can be cut will vary) |

| Rated Power | 9.5KW |

| Drive system | Servo motor, Linear guide rail, Rack |

| Motor | Delta |

| Nesting software | ET automatic nesting module improves utilization rate by more than 20% compared with manual operation |

| Data Format | DXF,PLT,PDF,AI |

| Transmission interface | Ethernet port |

| Fault detection | Automatically detect electrical faults when powered on and push codes to the system |

| Red preview function | Preview the cutting sample before processing to see if it is in the material to prevent misoperation |

| Projection function | Can install projector |

| Frame structure | Carbon dioxide protected welding bed, secondary vibration aging treatment |

| Voltage | AC 380V±10%, 50HZ/60HZ |

Advantages

This car mat cutting machine incorporates several key features critical for efficient and high-quality automotive mat production. Central is the exceptional cutting precision and ability to follow complex, vehicle-specific contours derived from digital templates, ensuring a perfect fit within each car interior. High operational speed significantly accelerates the production rate for high-volume automotive manufacturing. Integrated software includes advanced nesting algorithms specifically optimized for arranging irregular car mat shapes on material sheets to maximize yield and minimize waste, a crucial factor for cost control with automotive materials. The versatile tool head allows for processing various automotive mat substrates and thicknesses using the optimal cutting technology.