Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

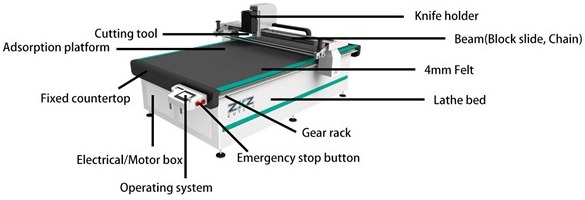

The CNC carpet cutting machine delivers impressive performance metrics tailored for the carpet industry. Cutting speeds are substantially faster than manual methods, drastically reducing production times. Accuracy is maintained across large surface areas and complex cuts, essential for high-quality finished products. This automation leads to significant gains in operational efficiency and throughput. Operation of this CNC carpet cutting machine is driven by Computer Numerical Control (CNC), allowing for precise execution of digital designs. The system utilizes specialized cutting tools, often high-power oscillating knives, engineered to slice through dense carpet fibers and backing materials cleanly. A robust vacuum bed holds the material firmly in place during cutting, preventing movement and guaranteeing the accuracy of intricate patterns and shapes.

| Parameter | ZXZ2516 |

| Working area | 2500mm x 1600mm |

| Cutting speed | 2000mm/s(Due to different materials,will affect) |

| Cutting tolerance | +/-0.2mm (The tolerance may vary due to different materials) |

| Cutting tool | Oscillating cutting tool / Round knife tool / punching tool (V-shape or circle shape) / drawing tool / CCD camera |

| Countertop type | Fixed working table OR Automatic feeding table |

| Material fixed way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

| Cutting thickness | ≤35mm (Depending on the material, the thickness that can be cut will vary) |

| Rated Power | 9.5KW |

| Drive system | Servo motor, Linear guide rail, Rack |

| Motor | Delta |

| Nesting software | ET automatic nesting module improves utilization rate by more than 20% compared with manual operation |

| Data Format | DXF,PLT,PDF,AI |

| Transmission interface | Ethernet port |

| Fault detection | Automatically detect electrical faults when powered on and push codes to the system |

| Red preview function | Preview the cutting sample before processing to see if it is in the material to prevent misoperation |

| Projection function | Can install projector |

| Frame structure | Carbon dioxide protected welding bed, secondary vibration aging treatment |

| Voltage | AC 380V±10%, 50HZ/60HZ |

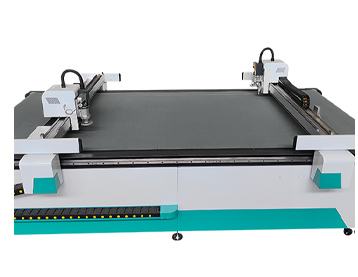

Efficiently and accurately processing bulky or fibrous materials like carpets presents unique manufacturing challenges. A CNC carpet cutting machine provides an automated solution designed to meet these specific demands. This system automates the cutting process, ensuring consistent results previously difficult to attain manually. The primary purpose is to enable manufacturers to handle various carpet types and thicknesses with speed, precision, and significantly less labor.

|

|

|

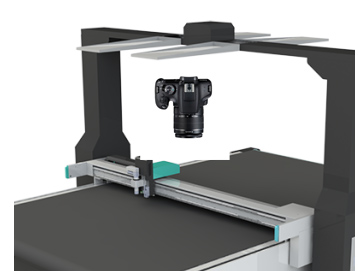

| Large-format material delivery platform | Large CCD panoramic camera positioning | Projector |

|

|

|

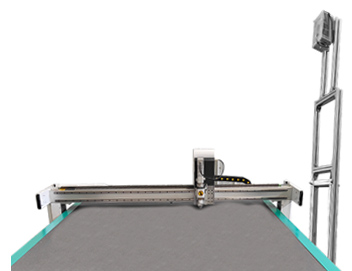

| Dual beams | Dual cutting tools shifting | Intelligent material calculation/layout software |

By adding additional configurations, the machine can achieve faster and more professional layout, autonomously identify patterns, quickly calculate cutting paths, reduce material waste, and accurately perform each cutting task.