Kathery Cui:

Whatsapp: +8615222735180

Email: cutcnc@chn-rubber.com

Diana Fu:

Whatsapp: +8618222051167

Email: zxzcnc@chn-rubber.com

Tianjin China Rubber Co.,Ltd

Contact Us

Email: cutcnc@chn-rubber.com

WhatsApp: 008615222735180

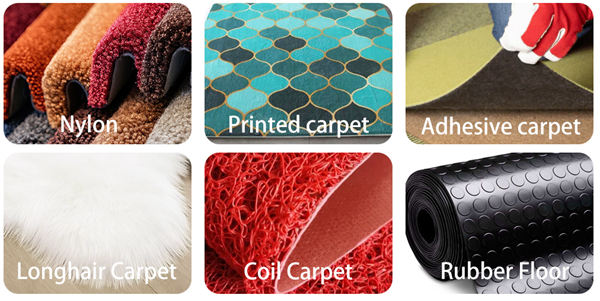

This floor mat cutting machine automates the cutting process, moving beyond manual methods to ensure consistent accuracy and high-quality results for different types of mats. Its primary function is to enable manufacturers to process mat materials rapidly and reliably, meeting demands for both standard and custom designs. Operation of this equipment is governed by Computer Numerical Control (CNC), allowing the precise execution of digital designs directly onto the mat material. The system utilizes specialized cutting tools, such as oscillating knives, rotary blades, or drag knives, selected based on the specific material type and thickness, to ensure a clean and accurate cut edge. A robust vacuum bed holds the flexible material firmly in place during cutting, preventing slippage and maintaining the integrity of intricate patterns and contours.

The most commonly used tools for cutting carpets are vibrating knives and circular knives. The thickness and hardness of the material to be cut determine whether to use ordinary vibrating knives and circular knives or high-power vibrating knives and circular knives.

| Parameter | ZXZ2516 |

| Working area | 2500mm x 1600mm |

| Cutting speed | 2000mm/s(Due to different materials,will affect) |

| Cutting tolerance | +/-0.1mm (The tolerance may vary due to different materials) |

| Cutting tool | Oscillating cutting tool / Round knife tool / punching tool (V-shape or circle shape) / drawing tool / CCD camera |

| Countertop type | Fixed working table OR Automatic feeding table |

| Material fixed way | Aluminum bellows type vacuum adsorption platform, partition / follow adsorption |

| Cutting thickness | ≤35mm (Depending on the material, the thickness that can be cut will vary) |

| Rated Power | 9.5KW |

| Drive system | Servo motor, Linear guide rail, Rack |

| Motor | Delta |

| Nesting software | ET automatic nesting module improves utilization rate by more than 20% compared with manual operation |

| Data Format | DXF,PLT,PDF,AI |

| Transmission interface | Ethernet port |

| Fault detection | Automatically detect electrical faults when powered on and push codes to the system |

| Red preview function | Preview the cutting sample before processing to see if it is in the material to prevent misoperation |

| Projection function | Can install projector |

| Frame structure | Carbon dioxide protected welding bed, secondary vibration aging treatment |

| Voltage | AC 380V±10%, 50HZ/60HZ |

This cutting machine incorporates several key features that enhance its performance and versatility for mat production. Paramount is the exceptional cutting precision, capable of following intricate contours and producing sharp, clean edges required for high-quality finished mats. High operational speed dramatically increases production throughput compared to manual methods. Integrated software optimizes material layout (nesting) to maximize yield and minimize waste. The versatile tool head system allows for quick changeovers between different cutting tools, adapting to various mat materials like rubber, carpet, EVA foam, leather, and composites of different densities and thicknesses.

The floor mat cutting machine finds broad application across multiple industries requiring precise mat fabrication. Key fields include the automotive sector, where it is used to produce custom-fitted vehicle floor mats, trunk liners, and interior acoustic materials. Residential and commercial applications range from entrance mats, runners, and anti-fatigue matting to custom-sized rugs and specialty flooring solutions. Manufacturers of recreational vehicle components, marine mats, aircraft interiors, and industrial safety matting also leverage this technology for efficient material processing.